| Transcribed and adapted by Janet & John Meads from: “The

|

|||||||||

|

|||||||||

|

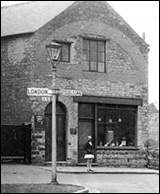

With the development which the parish of Burton Latimer has undergone during the last few years, the introduction of more manufactories and places of business, the old-fashioned methods of lighting by oil have become totally inadequate to the requirements not only of business, but of the general public, and after considerable discussion and the overcoming of many difficulties, a company was promoted by the leading residents with a view of supplying the place with gas. The company lost no time in getting to work, and have secured the services of Mr. J.T. Lewis, the engineer to the Wellingborough Gas Company, proceeded with the erection of gas works, which are now nearly completed, and it is hoped that within a few weeks the new illuminating power will be available for use. The greatest interest is felt in the event by the parishioners generally, who will receive benefit from it, inasmuch as the Parish Council have with commendable enterprise decided to immediately light the streets with gas, and as it is a matter of general concern, to the locality, a representative of the “Northampton Daily Reporter” has obtained from Mr. Lewis some particulars relating to the works. The works are erected upon a piece of land one acre in area, close to the main line of the Midland Railway and to the Isham station, forming an excellent site for the erection of the gas works, giving as it does direct railway communication for coal and other supplies without transhipment for carting. The danger of flooding has been avoided by raising the floor line 3ft. 6in. above the existing ground line. A siding has been constructed from the Isham goods department as far as the lime shed, for the conveyance of coal, lime, etc., coming into the works, and coke, tar and ammoniacal liquor going out of the works, thus giving the company a great advantage over many gas works, where the cost of carting is a serious item in the cost of manufacture. The buildings comprise retort house and coal shed combined, lime and purifier sheds, workshops, meter house, manager’s house and governor house; these are of a plain but substantial character in local brick. The retort house has a capacity of 20 retorts, but at present only five of these are set. The retorts are each 9ft. by 18in. – 15in. inside, fitted with ordinary retort fittings. With a view to economy in fuel, the retorts are heated by generator furnaces of a simple character. The coal shed has a capacity of 150 tons of coal. The hydraulic mains are D-shaped, of wrought iron, and the gas is conveyed from the main by means of a cast-iron foul main running round the retort house to the condensers, which are of the vertical type, and are for the purpose of cooling down the gas to about the temperature of the atmosphere. During the cooling process, most of the tar and ammoniacal liquor is brought down to the liquid state and carried by means of a main to the cast-iron store tank a few yards away. The gas passes from the condensers to the scrubber – this is a cylindrical vessel 12ft. high by 3ft. diameter, fitted with tiers of thin wood boards and upon the top of this is placed a water tank, from which a stream of water will be constantly running over the boards. The gas entering the scrubber comes into contact with a large area of wetted surface, the water taking up the ammonia of the gas with some of its other impurities. From the scrubber the gas will be conveyed to the purifiers, which are erected in the lime and purifier shed. These vessels are each 6ft by 6ft. by 3ft. 6in. deep, formed of cast-iron plates and a removable wrought-iron cover. The vessels are fitted with several tiers of wood grids; on each tier is laid a layer of lime about 8in. thick, the gas passing upwards through the lime; the latter having an affinity for the impurities in the gas; it takes them up, and the gas is then ready for use. After leaving the purifiers, the number of cubic feet of purified gas made is registered in station meter of 2,400 cubic feet per hour capacity, and from the meter it passes into the holder, which is 35ft. diameter by 15ft. deep, and has a capacity of about 14,500 cubic feet. The tank in which the gas-holder works is 36ft. 6in. diameter and 16ft. deep, built of brick with clay puddle backing. The gas as required will pass from the holder through a governor, where the pressure of the gas is regulated, and into the mains for distribution. The distributing mains which are laid in all the principal streets, etc., are of 5in., 4in., and 3in. diameter. The contractor for the building and tanks is Mr. Geo. Henson of Wellingborough, Messrs. Clayton Son & Co. of Leeds being the contractors for the general ironwork; the meter being supplied by Messrs. J. Milne & Co. of

|

|||||||||