| Article compiled by Sue Humphrey, February 2010 |

||||||||||||

|

||||||||||||

|

I joined Alumasc in or around 1971/72 as a switchboard operator. Mrs Zena Cooke, who lived in In those days STD (Subscriber Trunk Dialling ...... dial the number yourself rather than go through the operator!) was only available to people who had telephones in Kettering Corby or Wellingborough: everything else other than local calls were obtained via the local operator based in Kettering, where I was trained as a GPO Operator. In the first instance the office at Alumasc was located at the top of the back stairs in the block directly opposite the Foundry. It housed something called a 2-position PBX (Private Branch Exchange). Each telephone operator sat at each position.

You answered all the incoming calls. The telephone number was Burton Latimer 2121 (Weetabix was Burton Latimer 2181 - we often got one another’s calls!). You connected each incoming call to the relevant person/office that was required, but you also had to get every outgoing call for all the extensions. You soon learnt on a busy switchboard (as Alumasc was) to answer any incoming call, be dialling an outgoing call, and drink a cup of coffee - all at the same time! When Zena Cooke retired after about 6 months, Jo Ward joined. She then lived in In those days Mr Dick Woodward was Managing Director (extn 1, answered promptly!). Mr Cyril Inwood was Finance Director (extn 26 - also answered promptly). Kath Ramsden, who also lived in Bridle Road, was his secretary (extn 27), and the switchboard reported into Mr Michael Morton, the Company Secretary (extn 28 - ALWAYS answered first so as to keep on the right side on him!). He was a confirmed bachelor at this time, although much later on in his life he did marry: extremely formal, always addressing any married person as Mrs X, and only ever calling single females by their first name. His secretary was Pauline Hardy, who had a small “cubbyhole”-sized partition to his office as her own small working area. It may as well have been the

He was seen to be pedantic and "difficult", but I always found him very fair – just a stickler for office protocol and things being done absolutely correctly. He was never seen in anything less than a suit and tie even in 80 degrees of heat. Frank Sherwood was the Cashier who paid expenses and undertook trips to the bank!

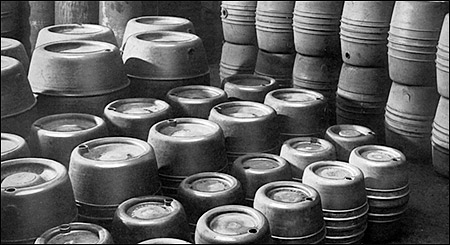

By this time Alumasc was known for its barrel production supplying barrels/casks and brewery equipment to then many breweries throughout the

When board meetings (boardroom extension 4) were held at Burton Latimer, the chauffeur would deposit the

Departments Some of the departments in those days were:- Garage - managed by Norman Blackwell. Alumasc had its own fleet of Lorries for deliveries throughout the

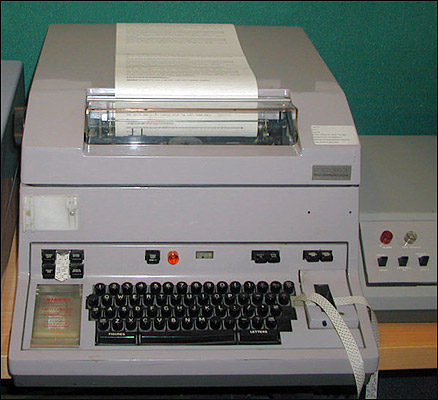

One driver we endearingly called “Hot Dinners” (Driver Parkin) only ever stayed somewhere that cooked a hot evening meal – hence his nickname. They were always addressed as Driver (and the surname) when they called into the office! Fettling Shop - This department got rid of all the lose bits off any castings etc (in very simple terms!). Managed by George Yeomans who was also the Sport and Social Club Secretary - the premises being situated at the end of Bridle Road. It had an active Bowls and Cricket Team and Social Club as well as many other sections. The Sports and Social Club was well supported both by the company and by Burton Latimer people. Boxing Day was always very popular at this club and queues would form from around 10.30am for doors opening at 11.00am – if you were late arriving: no tables left! There would be live music, dancing, bingo and raffles, and people would bring along sandwiches and make a full day of it, often returning in the evening to repeat the whole process again - a lot of fun was had by all who came The club entertained what seemed like half of Burton Latimer! Security - Alumasc employed its own team of security guards on duty to see goods, cars, and lorries in and out of the premises. All controlled by a very upmarket pole! A Buying Department for all purchases of office equipment and all manner of items to run a large company. Mr John Wilson, Ms Kath McDonough, Richard Nelson, Mr Alf Harrison became Senior Buyer. Metal Buyer Mr Palmer – who purchased all the metal used in the production process. His son John Palmer was a draughtsman in the drawing office. Ken Smith another bachelor who was Chief Cost Accountant He oversaw a Costing Office for preparing costings for every manufacturing item produced (Iris Grantham, Mick Dillon, John Robinson are some of the names I remember). This office always appeared to be very quiet as if everyone was concentrating on the figure work! Production Office – overseeing anything manufactured, and for planning it into the production schedule to meet delivery dates. People I remember were Walter Arthur, Tony Cotterall, and Geoff Patrick (Mollie's husband) who later managed the ladies in the Paint Shop Despatch run by someone called “Jock” Stewart, Roland Dacre, and Sue Griffin – they arranged for goods to be delivered. Norman Baish also worked from this office, I believe, unloading and loading goods Machine Shop for machining components – Sid Bland Barrel Shop - to begin with it was managed by Keith Walden, who later became Works Manager and Director. His secretary Jean Crampton still works there after 40+ years' service! Early in the 70’s Mrs Crampton was one of the first people to have a golfball typewriter and we all crowded round to gaze in amazement as the carriage remained in place and did not "return" when you had prepared a line of typeface. No more endearing “pings” heard when typing. This was modern technology at its highest point, and if I remember correctly it would also “self correct” typing errors as it has an “in built” correcting tape - no more "snow paint" when something was typed incorrectly! Most of the secretaries either specialised in audio typing – listening to a tape recording of what was required - or Pitman shorthand. The Barrel Shop was working a 3-shift system - 6-2 : 2-10 and 10-6. During the time of the 3-day week, somehow or other (and no one was every sure how) the Managing Director managed to get some sort of dispensation for the Barrel Shop to continue working when other production companies had to adhere to the 3-day working week. Drawing Office - full of apprentice trained draughtsman run by Peter Williams. Trevor Robinson, Peter Arnold, Mick Humphrey (later to become my husband), Barry Cooper, Bob Mills, Dave Robinson, Pete Warren were some of the names. Depending on what drawings were being worked, each draughtsman prepared them, recognized their own work, and also reported for their work given to them from the relevant product manager. The Drawing Office was a large upstairs open office looking out on to

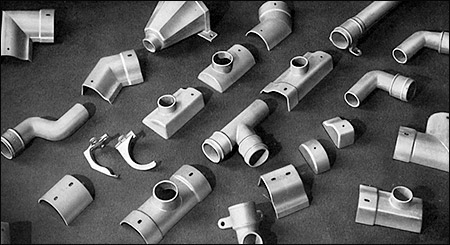

An active Research and Development area where ideas were developed. Roger Hyde and Barry Goodman, Mick Groome developed and worked here in various roles. Various Foundry Managers who specialised in each of the process: Jack Reed, Peter Howard, Gordon Brookes. One was High Pressure Manager, one was Low Pressure Manager and one was Gravity Manager. Chief Metallurgist Len Evans ensured the quality of the metal and its chemical reactions to heat – far too technical for a switchboard operator to understand even with “O” level Chemistry. Pattern Makers Pat Samways, Darrell Fieldhouse. These if I remember correctly made the patterns for the die castings A full Maintenance Team - Freddie Brown, Trevor Cotterall (Tony's father), Dave Eathorne (lives in Burton Latimer), and later on Geoff Kyte, who Mrs Crampton and I still refer to as Geoffrey bubbles bon-bon from a TV programme ! Forward Thinking - it employed a full-time nurse, who was on hand to remove pieces of metal from eyes(!), assist if accidents such as metal burns from molten metal occurred, and the doctor made a visit every Friday afternoon for appointments! (Doctor Kingsley) Other Staff Ashley Bellinger handled all the publicity- he came from Isham John Rowney - Rainwater sales office Stan Thorne (Roma Thorne’s husband) - Brewery Sales Office, processing Brewery orders Eric Rowbotham was Brewery Sales Manager Ken Hemmings Joyce ? who did the typing ! There were Brewery Sales Reps on the road, gathering the orders: Jack Hodgkinson - a lovely, jolly man - Nigel Cheadle and Paul Ruinet – they covered sections of the

Eric O'Loughlin was Sales Director ( lives at Grendon) There was very good canteen and an executive dining room that senior managers used (hallowed ground) with its own separate cook! Other names who were there included Alan Griffin Barry Mason who was in the Work Study Department along with John Inwood (Mr Inwoods’ son) and Trevor Jones - they did what was then known as Time and Motion. John Taylor who lived in

Russell Morris - Brass Castings along with Denis Marchant. They had come into the Akumasc "fold" through another company. John Donalek (who lived in

Other names were Mike Strowbridge, Tony Bryan, Gordon Peacock had various roles. Tommy Cleaver (lived in

Over the years Alumasc acquired a Plastics Department housed in a building at the back of the Catholic Church – headed up by Mr Roy Coleman. And a small premises in Desborough, managed by Mr Tom Pritchard. Forward-thinking Alumasc opened a small site in

The firm also took over the detached house opposite the main entrance as an overspill office.

Over the years the switchboard was relocated downstairs by the main entrance near the metal spiral staircase and we undertook reception duties as well as sending telex’s, and had one of the first fax machines. Telex’s were prepared on tickertape type strips of paper and when sending a long message you soon learnt not to tread on the tape as it split and would not transmit if broken ! This was the fastest way to send a document overseas at the time. The fax machine helped, as it could transmit drawings, and one sheet sent via fax took anything up to 4 minutes to compile on Thermo paper, and everyone was amazed you could send information over the telephone! We stood and watched it appear on the paper - however bad the quality ! Alumasc employed 3 retained firemen Kenny Arthill (who drove the fire engine), Alan Duck + a 3rd person. Part of our duties on the switchboard was that we would receive a call from the Burton Latimer fire station when the firemen were required, although they were issued with tone pagers and be asked to call them over the PA system and then count them off the premises. The signal that they were on the way was either thumbs up at the window as they passed or a bang on the window as they ran past ! All very primitive, but it worked. The best story I remember was the Alumasc had to contact the fire service for some incident and Kenny ran all the way to his car, then drove to the fire station to bring the fire engine back to the premises! The Christmas parties held at Just before I left in June 1979 Alumasc upgraded to the latest type of switchboard with "automatic ring" on all the cords. So when I left, office technology had moved forward, but nothing like we see today. It all sounds very archaic now, but ..... happy times! Sue Humphrey, Feb 2010 Click here to read about the first phase of the factory's life Click here to read about the development of the firm |

||||||||||||