| This article is based on the commentary to the Alumasc section of the Society's DVD. Original text seen and approved by Alumasc, 2007, and images used with their permission |

||||||||

|

||||||||

|

||||||||

|

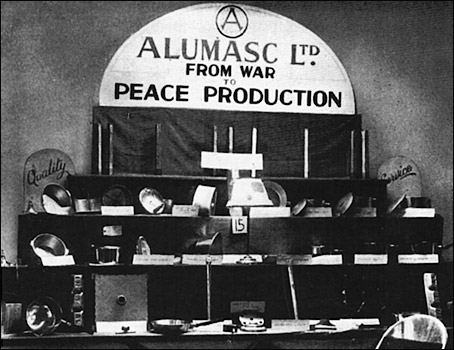

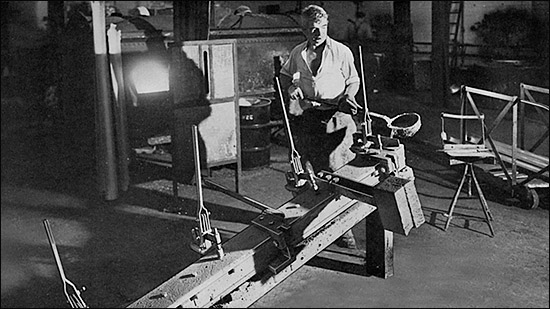

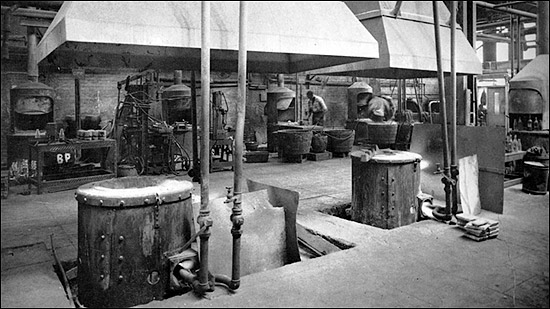

The Alumasc name came into being just after the end of the Second World War, when there was a management buy-out in partnership with London firm A Strauss & Company - the initials A, S and C of that firm were added to the first syllable of the word "aluminium" to create the name Alumasc, and establish its purpose and identity. The move from war material production to peacetime manufacturing also meant that the firm had to find new market niches and customers. The first range to be brought out was "Holloware" : aluminium cook- and bakeware. There was a ready market for it, and it was also a suitable product for teaching unskilled workers the new manufacturing processes involved in producing goods made from aluminium.

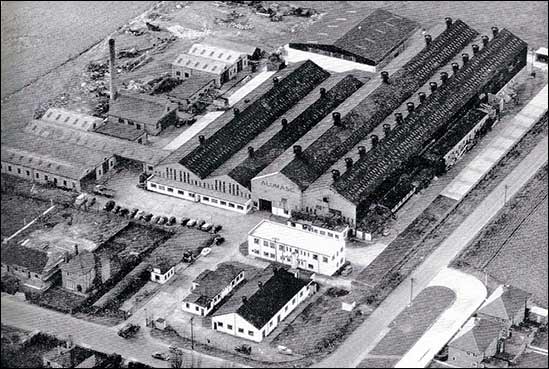

As output rose, as the skills were learned and the company became profitable, new machinery was acquired, and the company diversified its range to include things like rainwater goods such as downpipes and gutters. By 1948, the number of customer firms supplied by Alumasc had increased from 1 to 44.

Between 1949 and 1950 the company range expanded further to include products for the textile industry, the catering industry, and the brewery trade. The 1950s brought steady growth in range and output, and the increase in facilities and technology saw the factory grow in size. The customer base rose to 1100.

Further consolidation and expansion took place in the 1960s. The growth in the popularity of beer delivered in pressurised metal kegs rather than wooden barrels led to a large order from Guinness, and the product range was expanded further to include the manufacture of castings for the motor trade. Further diversification came with the development of brass casting. By the mid-60s, the company employed about 750 people.

Since then the company has consolidated its position and broadened its product range, responding to customer needs with the same expertise and investment which it pioneered at its inception. Much of the manufacturing process and related technology may have changed, but the present-day workforce follows in the traditions of manufacturing excellence laid down over half a century ago, and the company’s list of major customers testifies to the standards it achieves and maintains. The company continues to be a leader, and is here in

Click here to read about the first phase of the factory's life Click here to read Sue Humphrey's account of her time working in the office at Alumasc in the 1970s |

||||||||