| Article researched by Margaret Craddock with assistance from Mr Angus Westley. Presented by Margaret Craddock. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The business started on 1 January 1896 although it really began when two men used to walk three miles from Burton Latimer to To fulfil their dream of owning their own concern, they saved from their meagre wages in order to provide capital for their business. In 1895 they decided to work and save until Christmas and then to launch their own firm planning to work with the intention of retiring at the age of 50 if they were in a position to do so. They each managed to provide £50 capital and set up a workshop at

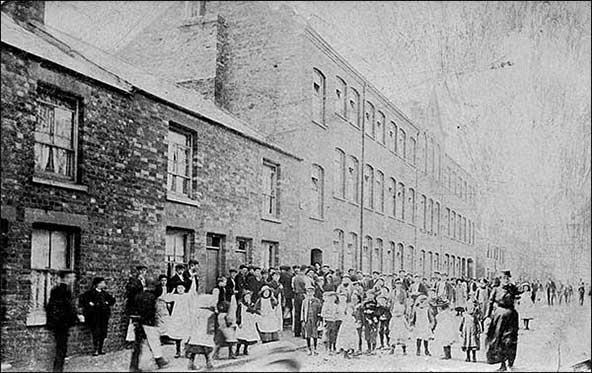

In May 1896, Mr Arthur Coles was employed as a packer and remained with the firm for more than 50 years. Mr Henry Sudborough who was employed as a clicker later founded Sudborough Bros of Wellingborough. In 1897, a plot of land became available opposite the cottage and was purchased to enable a three-storey factory building to be erected with production increasing to 1000 pairs per week. In 1899 ground level extensions were made and in 1904 six cottages and gardens below the premises were purchased to provide a further extension and double the size of the factory. Both the wives of Harry Whitney and Joseph Westley worked in the Closing Room to assist in the establishment of the business.

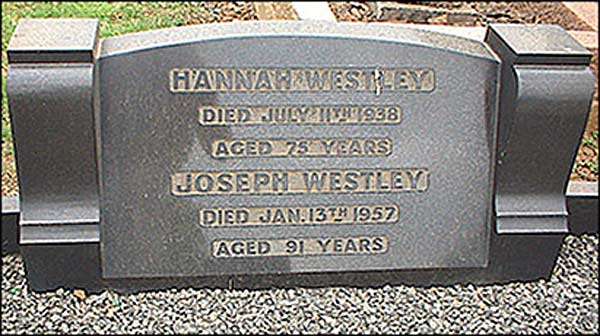

Joseph Westley and Harold Whitney always concentrated completely on their business and many a night they remained at the factory working until dawn broke, letting in the operatives in the morning without having had a wink of sleep. This dedication enabled them to realise their ambition on 31 December 1913 to retire at the age of 50 having worked in the industry for 40 years. Mr Westley reached the age of 91 when he died on 13 January 1957. (To read his obituary click here and about his will click here.)

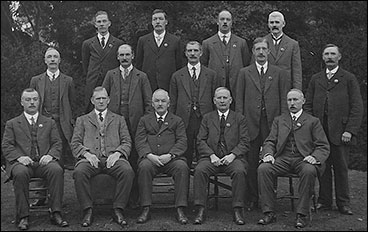

The control of the business was passed to Frank and Joseph, the sons of Joseph Westley and Harold Whitney. Mr Oliver Tailby joined the firm in 1900 as a part-time office boy and became a Director 18 years later. Mr Wright Harris became a Director at the same time as Mr Tailby but retired after two years.

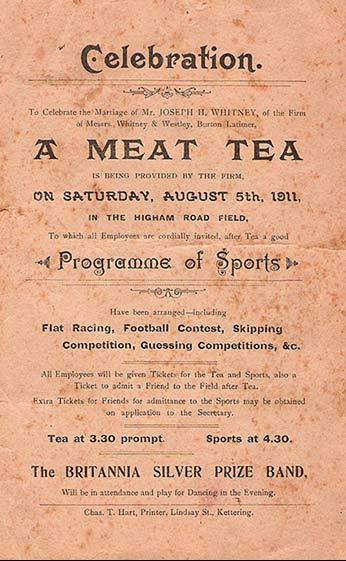

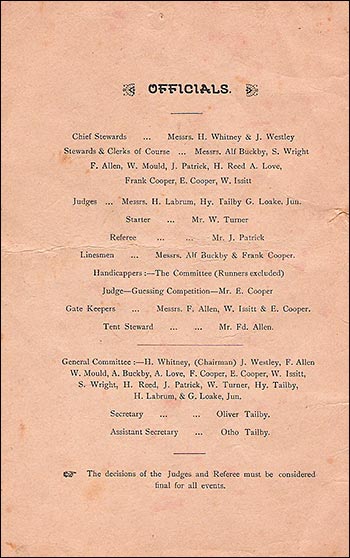

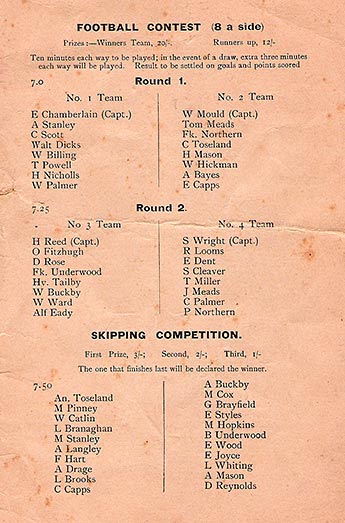

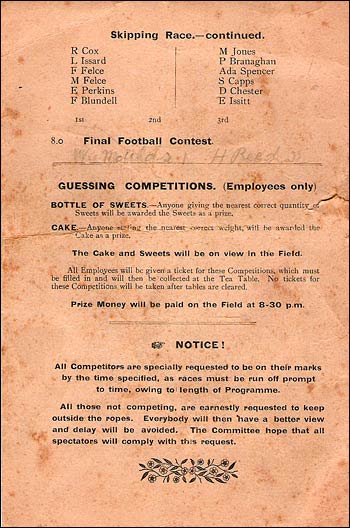

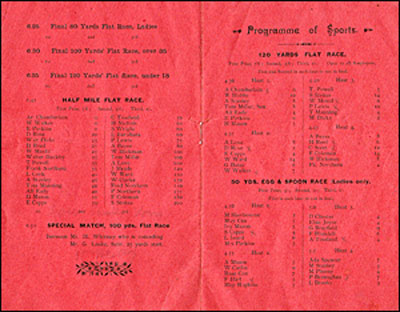

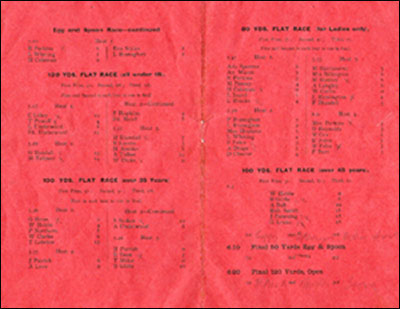

In 1911 all employees were invited to a Meat Tea and Programme of Sports Activities in the Higham Road Field. This event was held to celebrate the marriage of Joseph Whitney. The chief stewards on the day were Mr Harold Whitney and Mr Joseph Westley and the Secretary, Mr O Tailby. The programmes are shown below:

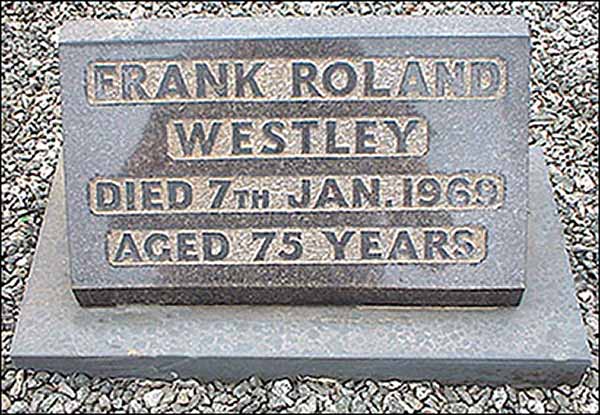

Frank Westley and Joseph Whitney took over the old malting premises in the town from Mr Charles Barlow and founded the Standard Boot Co in which Mr J W Coles was their partner. Mr Coles represented the company as a traveller, became a partner and changed the name to Coles Boot Co. From 1922, Frank Westley became the sole Managing Director following the death of Joseph Whitney. Mr Westley remained at the factory until 1950 when ill health forced his retirement and his death occurred in 1969 at the age of 75.

One former employee recalled working at the factory in 1915. He lived in Finedon and used to walk past In 1929, the Wellingborough branch factory was opened. Further extensions occurred in 1930 when coke bunkers at the rear of the Burton Latimer factory were converted into a sizeable extension to accommodate the Bottom Stock and Heel Building Departments. This building was later used by the Instock Division (Angus Westley Shoemakers Ltd) serving independent retailers at home and abroad with Angus Westley branded shoes. The Instock Division was established in 1947 replacing Mediator Shoes which had been in operation from the mid 1930s in Click here to read about the funeral in 1933 of Walter Summerfield, Factory Manager, aged 46 years.

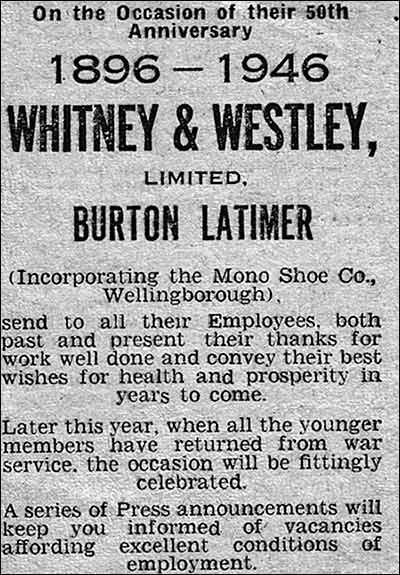

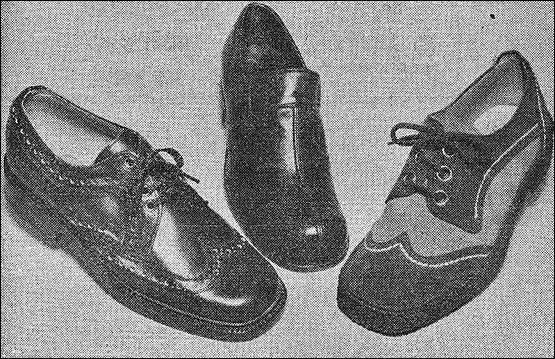

In the 1930’s, Eric Ambler worked in the office. Following army service he joined the Coles Boot Co as a representative and later became Design Director and then Sales Director. He designed the first pair of shoes for a star – Cowboy boots for Tommy Steele. During World War II, from 1939-46, army boots were the main production but other types of service footwear were also manufactured. Half a million pairs were made – a creditable achievement in view of the fact that the whole of the Bottom Stock department was taken over by the Ministry of Aircraft Production. Buckby Bros, another Burton Latimer firm, also shared part of the factory and a considerable amount of co-operation was required to enable both firms to make best use of available materials and personnel. Later in 1946 both Buckby Bros and the Ministry of Aircraft Production left the premises. At this time too, the building was redecorated internally and new cloakrooms were installed. Individual motors were fitted superseding all shafting. A weekly production of 7000 pairs was planned, half of which were to be ladies welted shoes. In 1973 the weekly output was 6000 pairs of mens shoes. At that time 60% of the 250 employees were women. 50th Anniversary Jubilee Celebrations

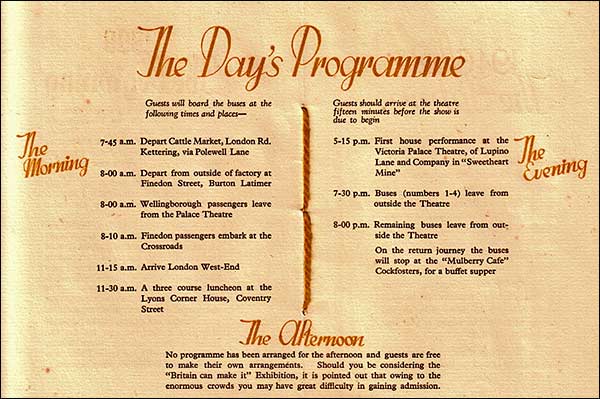

In 1946 the firm celebrated its 50th Anniversary and, on 23 November, 200 employees with 80 friends were treated to a day in

Items from the Jubilee programme include the following:

THEY WERE EARLY BIRDS AT

Never call to see anyone in the

You won’t be popular for they’re all “twelve o’clock lunchers” at

The reason is that years ago

Since then they have adopted 7.30 as a starting time, but midday lunch is still the rule.

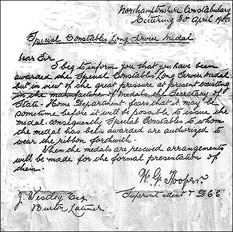

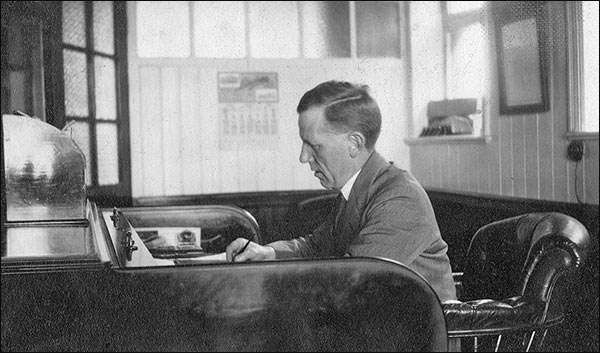

In 1946, Mr Angus Westley returned from service with the RAF and became a Director and on his father’s retirement in 1950 became joint Managing Director with Oliver Tailby. Mr W E Billing of Wellingborough who was Works Manager retired owing to ill health in 1945 to be succeeded by Mr Herbert Dunmore. Mr Dunmore joined the firm as a boy in the Lasting Room. He left the firm in 1938 to work with another manufacturer, Wilson & Watson Ltd, Kettering but returned to Whitney & Westley in 1946 as Works Director. He was an outstanding personality and a highly regarded practical shoemaker. (Click here for newspaper article of Mr Dunmore's death) In 1957, Mr J H Matthews, who was Company Secretary, became a Director, and finally Joint Managing Director with Angus Westley. Mr Oliver Tailby retired in 1961 (click here to read his obituary) and Mr Dunmore in 1968.

In 1925, Frank Westley pioneered the company’s overseas selling by undertaking a round-the-world trip and established contacts in

During the 1950’s a close association was formed with The Coles Group of factories. A Wellingborough factory in DOWN YOUR WAY In 1973, Mr Angus Westley was interviewed for the BBC Down Your Way programme hosted by Fyfe Robertson, when it visited Burton Latimer. As Managing Director of Whitney & Westley Ltd he described the production of footwear by his company. DEPARTMENTS WITHIN THE FACTORY

The main processes used in the manufacturing of shoes:- 1 CLICKING This is a process where the skins, hides or man-made materials are cut into the shoe upper sections. Click here for memories of Tony Palmer. 2 CLOSING To produce an upper, the various upper sections are stitched together. 3 BOTTOM STOCK This is where the process of cutting and preparing bottom components (such as soles and insoles) takes place. 4 LASTING Gathering and shaping the assembled uppers on the last and fixing the upper on to the insole. 5 MAKING A number of processes by which heels and soles are attached to the lasted shoe. 6 FINISHING The process of improving the durability and appearance of the shoe by various operations such as bottom securing and edge trimming. 7 SHOE ROOM Where all the cosmetic operations take place, such as upper cleaning and dressing, insertion of socks, final inspection and boxing. Click here for Gallery of Photographs of various processes in the factory

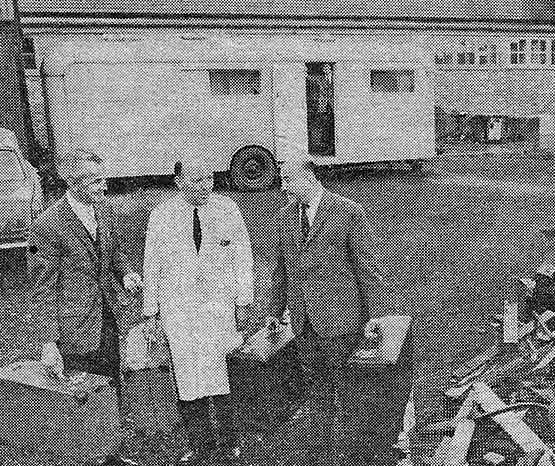

FIRE AT THE FACTORY On Saturday, 14 June 1969, a large section of the factory was gutted by fire with the first and second floors collapsing. Workers were at the factory until 11 am on the morning of the fire and the Caretaker was alerted to the blaze in mid-afternoon. Many employees assisted in removing charred remains from the building once the fire was under control and helped throughout the weekend with the clearing-up operations. One of the items recovered from the fire by a helper was Mr Westley’s passport. After investigation, the description of the fire by the Fire Investigation Officer was that it was a ‘High Level Fire’.

This was a peak production time for the business with over 200 employees. The workforce was concerned that their jobs would be affected. The disaster struck at a very healthy period of production that had resulted in a record week for despatching. All leather stocks together with quantities of shoes for export were destroyed as was part of the production area, the Finishing and Shoe Rooms being severely damaged. The Office area was also ruined. Five days after the fire many employees were back at work. The Closing, Lasting, Making and Bottom Stock departments were unaffected by the blaze and only slight damage occurred in the Finishing Room. Shoe Room workers were able to return a few days later and the Clickers the following week. Leather suppliers co-operated to replace requirements as the entire upper leather stock was lost in the fire.

Mr Ted Reed, Sales Director, managed to leave for an export trip to

The following letter written by Angus Westley was published in the local paper:

The office and showroom was temporarily installed in the factory canteen and then located in part of the Bottom Stock Department until the new office block could be built. In 1971, two years after the fire, the factory was again back to normal production, the final restoration being the office block. The subsequent building was more modern in appearance and well laid out with maximum use of floor space, better lighting and decoration and a more scientific flow of work.

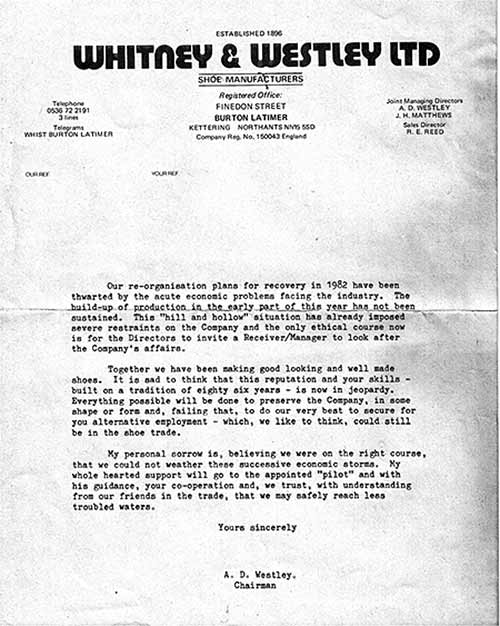

CLOSURE Just over ten years after the fire, due to the economic situation, the Directors were forced to appoint a Receiver/Manager to look after the Company’s affairs.

Many footwear manufactures were placed in a similar position at that time with the shoemakers union losing over 20,000 members in just three years – mainly from Northamptonshire. The demise of the industry was largely due to cheap foreign imports. From being the centre of the shoe industry, the county firms were struggling to survive. Records of the company from 1897-1977 can be found at the Northamptonshire Records Office (Ref: NRA22298 Whitney). These include financial records, purchase analysis book, customer accounts, wages books, price lists, copy drawings and plans. Mr Angus Westley became involved with a new company making his own branded footwear. The uppers were produced in a small Closing Room in Burton Latimer and the finished shoes produced in a factory at Finedon. The shoes are stocked by retailers today. In fact they are available worldwide from numerous outlets to be found on the Internet – even on eBay. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||